Kirchheim/Teck

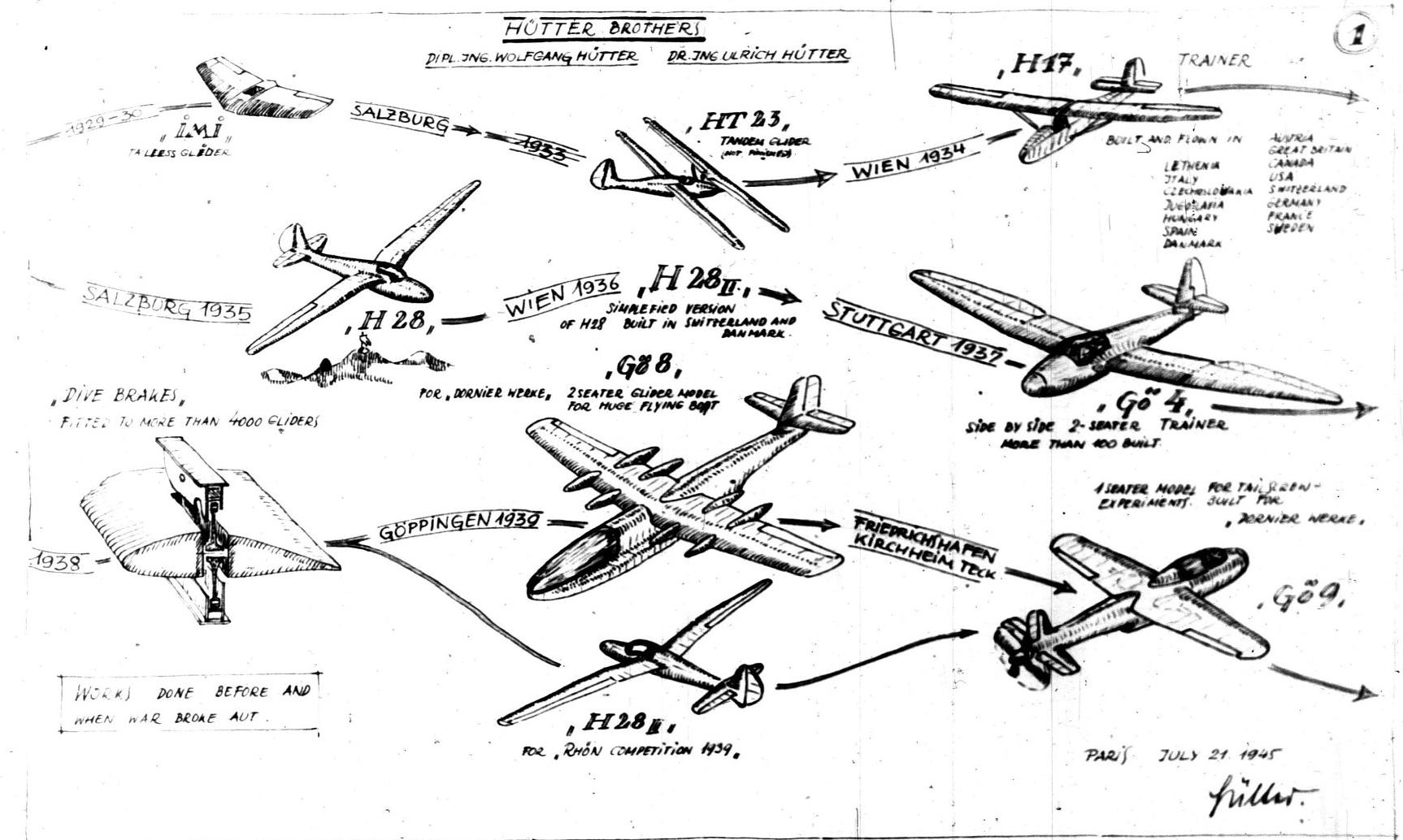

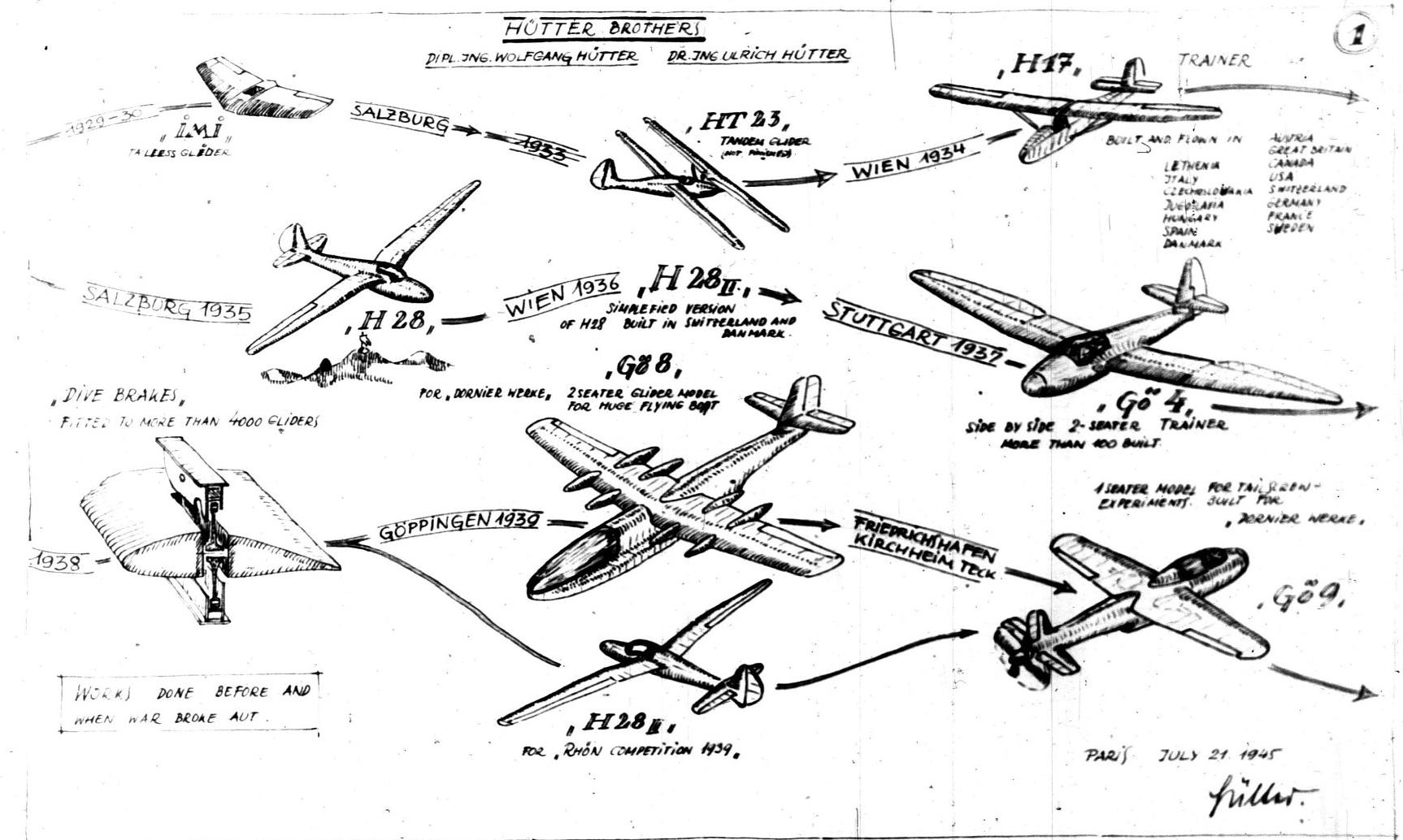

1929-30 IMI tailess glider

1933 HT 23 tandem wing glider

1934 H 17 glider trainer

1935 H 28 glider

1936 H 28 II simplified H 28

1937 Gö 4 glider trainer

1938 H 28 III competition glider

1939 Gö 8 2 seat flying model of Dornier 8 engine flying boat

Gö 9 1 seat pusher test aircraft for Dornier

1941-43 Design of ailerons, flaps and horizontal stabilizer Me 321 & Me 323

1941-43 Windmill powerplant design

1942-43 Design wooden wing for Bf 109

1942-43 Hü 21 High performance 2 seat glider

1944-45 Hü 211 High altitude long range version of He 219

1944-45 Low drag auxiliary tanks for Fw 190

1945 Single seat fighter with 2 Argus jets

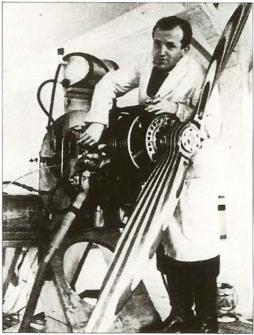

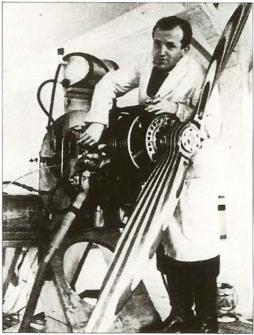

Prof Dr-Ing Ulrich Hutter (1910-1990) at work

on an aero-engine. Together with his brother

Wolfgang, he became well-Imown through the

design of high-performance sailplanes (eg the

Schempp-Hirth Go 4 and Hi 20 'Mose' of 1937, and

for his development of dive-brakes used by the

DFS in 1938). During the war, The brothers

developed various projecls of the so-called

'Ostmark' series, among them the tong-range

Zerstorer and various long-range reconnaissance

and bomber aircraft.

Wolfgang Hütter

He was born in Vienna on 2nd October 1909. As he was the son of the builder of the first Salzburg theatre (Festspielhaus), Wolfgang spent his youth in Salzburg and it was there that he designed and built his first aircraft which luckily were not brought to flying stage. It was in Salzburg that he, and his brother Ulrich, the later aeronautical professor and wind energy pioneer, designed the minute H 17 sailplane in 1934, which he himself, during the same year, test flew from Gaisberg (at Salzburg). Many of these were built by amateurs and some are stiIl flying today in, among other countries, far away Australia. Its wingspan was less than 10 metres and the number 17 refers to its max. glide angle, which is the same as that of the larger Grunau Baby_ Il was whispered after the war that Hütter was the best glider designer, for he could do what others could do... but with a sailplane a fraction of the size of the others. Indeed the H 17 could fly a pilot of its own weight !

Shortly after the H 17 he designed the first H 28 with theoretical max. glide angle of 1:28... (actually this was proved as 1:27) with its 12 metre span. This was typical of Hiilter's design theory: small, manoeverable, with fuselage of minimal cross-sectional area by fitting the pilot's elbows into the wing roots, which was a characteristic of his later Goevier (1938).

The first H 28 was built in incredibly short time, patronised by Graf Kinsky, in an ideal workshop in 1934 in Austria. Many new ideas were tried out including a blown canopy and retractable verturi. The 12 metre span H 28-2 was designed in Salzburg in 1936 but was never built in Austria. Two were built by an Austrian group in Czechoslovakia, two in Switzerland (of which one went to Rhodesia), and one inDenmark during the war .

After Austria had become part of Germany in 1938, Wolfgang and Ulrich Htitter took up employment with the Sportfiugzeugbau Goeppingen and it was during this time that the Akaflieg Stuttgart nearby built a larger version of the H 28 (the H 28-3) with a 13.5 metre span. This machine was brought to the 1938 Rhon contest in a little closed trailer, towed by one of the first VW Beetles. It caused a sensation.

During 1938-39 Wolfgang Htitter first showed an interest in trying to create aircraft components in plastic construction. This was used for the Goevier's wing/fuselage joint creating

an almost aerodynamically perfect wing root, into which both pilots' outer elbows fit, to reduce fuselage cross-sectional area (for less drag).

During the war, he would have been involved in projects being undertaken by the Schempp Hirth firm such as the huge ME 321 and the ME 323 tail assemblies, the Hi 20 (Hi for

Hirth) motorglider (Mose), the Hi 21 variable wing sweep side-by-side two-seater with double retracting undercarriage, the Go 8, a scaled down version for testing of the large

Dornier 214 flying boat of 1938-39 and the Go 9, a scaled down test aircraft with rear pusher power for the Domier 335 "Pfeil" of 1940-41. Also tailplanes, elevators and rudders

were designed and built out of wood for the ME 109K and many would have equipped this fighter during 1945. However the wooden wing, complete with spars, for the ME 109

was found to be too complicated, although one was built.

During late 1938, the RLM commissioned the Schemp Hirth firm to design airbrakes limiting speed to a safe maximum, on account of the many accidents in cloud during the

final days of the 1938 Rhon contest (seven sailplanes broke up, there being three fatalities).

The Hütter brothers were responsible for these airbrakes and they became obligatory for all NSFK sailplanes, even if they had been already designed and built without them. They

were mass produced in kits by two firms for all types of gliders. They were also planned to be used for aeroplanes. The Goevier was the first sailplane to be designed from the outset

to have them. During tests with the Goevier with a loaded weight of 400kg. (8801b.), these airbrakes were not efficient

enough to hold the machine back. The RLM then required it to fly with a loaded weight of 410 kg and this compeIled Wolfgang Hiilter to design more efficient "paddle;'

brakes. Even these would not hold the machine back and a whole aileron carried away with part of the wing. Wolfgang

Hiiner accompanied the test pilot Clompe on many of these test flights but was not with him during the accident, when both pilots successfully escaped by parachute.

It has to be said that both ME 321 and Goevier were to be used during the 1941 planned invasion of Britain, but in the event the 321s Were sent to Russia to supply troops in the

snow during the 1941-42 winter, and they could not be retrieved out of the' snow. The Goeviers were never used in action..

The Goevier 2 was already too heavy due to it having to carry nose ballast:caused of its C of G being to far aft.

Nethertheless, itt was mass produced like this during the war.

In May 1944, Wolfgang Hütter left Wolf Hirth's firm to form his own Hütter GmbH nearby. This was due to his preoccupation to design and build a plastic aircraft. The Horten

brothers had already during 1944 pioneered the use of a wooden shell construction formed on a mould for their Harten 4B flying wing sailplane. Wolfgang Hütter intended ,to use

this method of construction to build a one-plane with 24.5 metre wing on a 25 metre long concrete heated mould as a plywood and glue shell, for the long distance reconnaisance Hüller 211. This was to be powered by two Jumo 211 which were to enable it to reach a relatively high speed at great height. The fuselage was basica'l\y that of the Heinkel 219 "Uhu" but it was to be built of wood rather than metal. Its tailplane was a "butterfly" of wood, .. as that of the H 30 sailplane. The use of wood replacing the metal would have resulted in an important saving of weight. Much test work and building of mock-ups had been completed and the heated mould was almost

ready when the workshops were occupied by aIlied troops in May 1945.