| Type |

2-seat carrier aircraft |

| Engine |

6 Daimler-Benz DB 603 N |

| Dimensions |

Length 35 m , height 12 m , span 54 m , wing area 500 m2, aspect ratio 5,8, Wing area of the attached high-speed bomb carrier

(140 m*) is included |

| Weights |

Empty 48500 kg, loaded 122000 kg , max. take off weight fuel 3000 kg, oil 300 kg, crew 200 kg |

| Performance |

Max.. speed 560 km/h, cruising speed , range , endurance , service ceiling , climb 7,6 m/sec. required start run 500 m |

When the enemy bombing raids could no longer be controlled towards the end of the war, people began to think, albeit too late, about how they could ward off these bombing raids in the future. The most obvious thing to do was to build high-performance fighters and destroyers that would be able to directly attack enemy bomber squadrons and their escort fighters. It was expected that the enemy would then only carry out its bombing raids with fast combat aircraft in night and bad weather missions. In order to combat these fast enemy fighter aircraft, Focke-Wulf designed a night and bad weather fighter with a Jumo 222 E/F piston engine and two BMW 003 jet engines. We reported on this project in detail in the first part of our series on unknown Focke-Wulf projects (aerokurier 7/64, page 317). Another solution to defend against enemy bomber formations was seen in the destruction of enemy airfields, hangars, supply bases and fuel transports. Within a day or two, these bases and the aircraft based there were to be bombed and destroyed on a large scale in a surprise attack in order to paralyze the enemy bombing raids for at least a certain period of time, so that our own industry and the transport network could recover during this time. This would have created the possibility of being able to resume our own fighter production and fuel production on a large scale during this rest period. However, it seemed to have been forgotten at the time that this line of thinking would remain utopian. too much space was available for our bomber deployments.

Development of a high-speed bomb carrier

Such a surprise attack against the enemy could not be carried out with normal bombers, even if they reached a speed of 600 km/h or 700 km/h, as the losses caused by the enemy's fighter aircraft would have been too great.

In addition, the industrial capacity at the time would not have been sufficient to produce a bomber of normal design in such large quantities as was necessary for such a surprise attack. Therefore, at the beginning of 1945, Focke-Wulf, based on a suggestion from Daimler-Benz (Project B), designed a high-speed bomb carrier, which had the following requirements:

1. The flight speed had to be at the limit of the speed of sound in order to rule out defense by enemy fighter planes, which could not be faster given the state of technology at the time. 2. A favorable ratio of construction costs (empty weight) to take-off weight had to be achieved.

The bomb load therefore had to be significantly higher than that of previous bombers. 3. However, the aircraft had to be smaller than conventional bombers in order to save on equipment and labor costs. These requirements meant in concrete terms: a bomb load of 30 tons, a penetration depth of around 1000 km/h and a cruising speed of around 1000 km/h.

Technical implementation

The technical implementation required a purely single-purpose aircraft that, for performance reasons, had to forego any offensive or defensive armament. Defense was to be ensured only by superior speed. These requirements required a high wing loading of 500 kg/m*, which in turn resulted in a very high take-off speed. A take-off weight of 70 t was expected, for which the undercarriage and tires would have had to be dimensioned. However, this dimension would not have allowed for retractable undercarriage. In addition, the high take-off speed would have required not only concrete runways, but also, given the state of technology at the time, starting aids such as powder rockets or Walter devices, for which fuel was hardly available at the time. Such devices would easily have led to false starts and thus to the destruction of the aircraft. In addition, the ground facilities were a preferred target for enemy bombers. In addition to the requirements listed above, the ability of the high-speed bomb carrier to take off and land at any ordinary field airfield was also required. How was this problem solved?

Take-off by carrier aircraft

For take-off, an additional wing and a correspondingly strong undercarriage had to be "borrowed". This assistance was to be provided by a carrier aircraft, one for every three high-speed bomb carriers. The high-speed bomb carrier was to be suspended under the carrier aircraft. This design was preferred to the already common "piggyback" in order to enable loading from below using normal bomb loading equipment. It was believed that the combination with a total take-off weight of 122 t could take off from any normal field airfield and keep the taxi distance to around 500 m. However, the carrier aircraft was not only to take off the high-speed bomb carrier, but also other special aircraft with a high wing load. In addition, it was hoped that its help would enable the unit to be moved quickly from one place to another, as its design would allow it to be could have been used to a certain extent as a large transporter to transport the entire baggage train.

This solution had the further advantage that a large part of the components of the high-speed bomb carrier, such as the retractable landing gear, only had to be designed for the landing weight of the empty aircraft. This meant that the ratio of construction effort (empty weight) to bomb load could be kept far more favorable than with all previous bombers. Landing itself was not a problem, since the wing loading of the empty aircraft was around 200 kg/m*. If the site had been relocated, the high-speed bomb carrier could have taken off with a correspondingly small amount of fuel and without a bomb load, even without a carrier aircraft, so that the carrier aircraft could have been used purely as a transport aircraft.

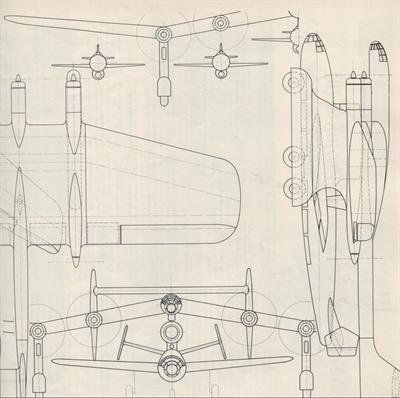

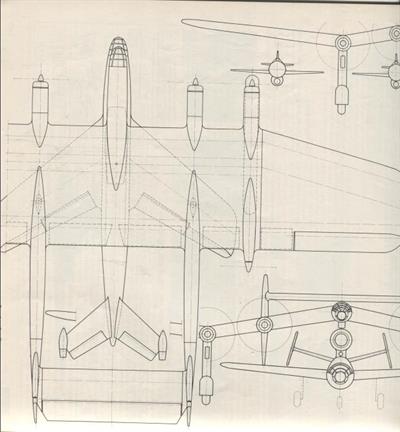

The carrier aircraft

The carrier aircraft was primarily intended as a start-up aid for the 70-ton fast bomb carrier and other special aircraft with a high wing load. The mid-wing aircraft with a gull wing, tail boom and fixed undercarriage could also be used as a large transport aircraft.

Hull structure

The two-man crew was to be accommodated in the partially glazed front section of the fuselage. The central fuselage contained all the equipment and the winch with the motor for the heating system.

Wings

The rectangular outline of the inner wing had a wing depth of 11 m. The outer wing was tapered from 11 m to 7.5 m. In total, with a span of 54 m, the wing area was 500 m2. The thickness ratio was 14 percent at the wing root and 9 percent at the tip.

The box spar was arranged at approximately 30 percent of the wing depth. The upper bottle of the heating system was located in the middle of the wing. The heating harness absorbed the forces in the direction of the vertical axis, which were deposited directly on the spar. Two support struts were attached 7 m from the middle of the aircraft to absorb the forces in the longitudinal and transverse directions and to absorb the moments that occurred.

Landing gear

The fixed landing gear had six wheels measuring 1880x680 mm, with the front pair of wheels being arranged so that they could be steered. The crew entered the aircraft in the undercarriage fairing. From there, a corridor led through the wing to the fuselage and into the cockpit.

Engine

Six Daimler-Benz DB 603 N engines were planned for propulsion. The propellers were four-blade propellers with a diameter of 5 m. Four engines of standard design with ring coolers were to be attached to the front spar, two engines were to be installed in the wing behind the main spar. The cooling system for these two engines was located in the chassis fairing. The propellers of the two engines were driven by shafts and worked as pressure screws. The fuel was housed in the box spar. The lubricant containers were located next to the engines.

Hanging process

After the high-speed bomb carrier was loaded, the carrier aircraft had to be brought into a position so that the hot gear was hanging exactly over the bomber's center of gravity. The bomber was then to be grasped by a lug and hoisted up against the two supports with pre-tension. To take off the team, all that was needed was to retract the undercarriage of the attached aircraft.