In November 1936 the prototype Fokker G.I heavy fighter caused a sensation when exhibited at the Paris Air Show, which in those days did not have a flying display but only a static exhibition in the Grand Palais. The concept of a twin-boom twin-engined fighter, later adopted for the Lockheed P-38 Lightning, was revolutionary at the time, and the new aircraft was the centre of much critical appraisal.

After the Show, the G.I was taken to Eindhoven/Welschap airfield, from where its first flight was made on 16 March 1937. The G.I was then powered by two 559kW Hispano-Suiza 80-82 counter-rotating radial engines, but problems with these prototype units resulted in a change to similarly rated Pratt & Whitney SB4-G Twin Wasp Juniors during reconstruction, after the G.I suffered brake failure and rammed a hangar at Schiphol on 4 July 1937.

Demonstrations had already been given to the Netherlands army air corps at Soesterberg, and considerable interest was shown, resulting at the end of the year in an order for 36 aircraft to be designated G.IA. In order to ease the spares situation, it was stipulated that these must have Bristol Mercury VIII engines, which were also to power the T.V bomber and D.XXI fighter already on order for the air corps.

This decision brought delay because although G.IA production began immediately there was a hold-up in the supply of engines. Thus the first production aircraft to fly, actually the second of the batch, became airborne only on 11 April 1939. It remained with the makers for production testing and modifications, and the first aircraft was delivered to Soesterberg on 10 July 1939.

Possibilities of export orders followed the aircraft's debut at Paris and a number of foreign pilots came to Fokker to fly and evaluate the G.IB export version. Orders were placed by Finland (26), Estonia (9), Sweden (18) and Republican Spain (12), while a licence-production agreement was in negotiation with Denmark and another with Manfred Weiss in Hungary. The Dutch embargo on weapons exports before World War II killed the Spanish order, but the Finnish batch was under construction when war broke out and a ban was then placed on its export. After lengthy negotiations a contract was drawn up to permit the G.IB's export on 17 April 1940, by which time 12 had been completed, apart from armament.

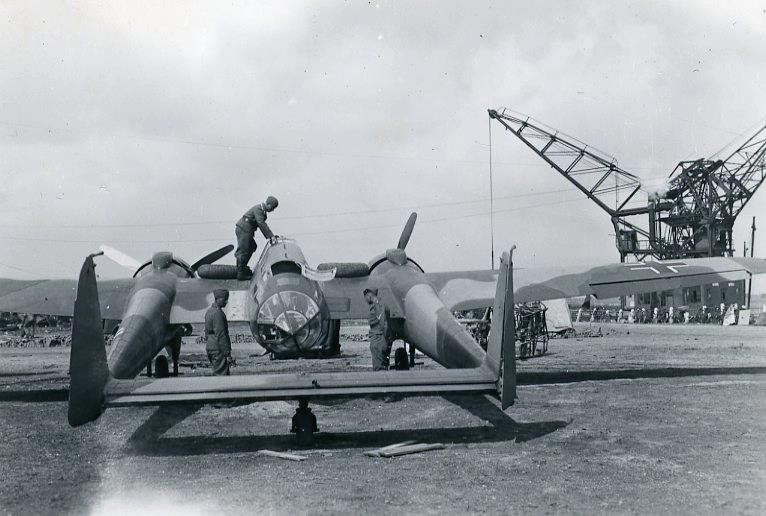

When Germany attacked the Netherlands on 10 May 1940, 23 G.ls were in service: 12 with the 4th Fighter Group at Alkmaar and 11 with the 3rd Fighter Group at Rotterdam/Waalhaven. The G.ls were successful in destroying several'Junkers Ju 52/3ms during the early stages of the German invasion, but by the fifth day, when Dutch resistance ended, only a single example remained airworthy.

The Germans occupied the Fokker factory, ordering completion of the 12 G.ls intended for Finland, and these were used subsequently by the Luftwaffe as fighter trainers. Test flights from the factory were made under German supervision, but on 5 May 1941 two Dutch pilots succeeded in evading an escorting German-flown G.I and escaped to England. Their G.IB was taken to the Royal Aircraft Establishment, Farnborough, for examination, and used subsequently by Phillips and Powis (Miles Aircraft) at Reading for research into wooden construction.

A total of 62 G.ls is believed to have been built, and none survived the war.

It cannot be stated with certainty how many G-1s have finally been captured by the Germans. It may be assumed that various types Mercury and Wasp have been landed undamaged in German hands. Also it may be taken for granted that a number of the Danish aircraft have ended up undamaged with the Germans . It is almost certain that some thirty aircraft have entered service with the Luftwaffe, but of about twenty further aircraft the ultimate fate is still unknown.

Germany used the G-1 mainly as test aircraft and training aircraft. With one of those test aircraft Messrs. Leegstra and Vos succeeded to escape to Great Britain on May 5th , 1941, during a daring raid. This aircraft has finally been destroyed by the harsh British climate being a test vehicle for the Miles aircraft factory. It is not completely known how the German Air Force allocated the German G-1 aircraft with the various units. In any case the Aircraft Flying Schools [Flugzeugführerschule] C8, C11 and ZS 1 have utilized the G-1.

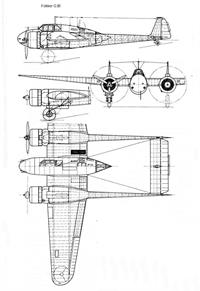

The G1 was designed and a first prototype was built in 1936 by Fokker head engineers Beeling and Schatzki, with the design and building of the prototype taking just 7 months. Work had actually started in March 1935 after receipt of a specification from the French Airforce for a two engined heavy fighter that was supposed to utilize French equipment: Hispano Suiza engines, instruments, and a landing gear to be delivered by OLA. French interest disappeared after several French designs subsequently appeared. Fokker however thought the design had potential and continued development on their own initiative as “Project 129”. The aircraft had a twin boom configuration, something which was not new, but which caused a great public sensation when first seen. In the fuselage there was room for both the crew and the aircraft’s armament. The armament was in the nose: the prototype had 2x23mm Madsen cannon with 100 shells and 2×7.9mm machineguns with 550 cartridges, and was connected to the framework for the front of the central pod.

Like all Fokker aircraft of the period (and many aircraft constructed by other manufacturers at this time), the G1 was of mixed construction; the front of the central pod and the tail booms and tails were built around a frame of welded steel tubes covered with aluminium plating. The back of the central pod, however, as well as the wings, had a wooden frame, covered with triplex, a technique also used in Fokker’s successful passenger aircraft at that time. The steel tubular frame was attached to the front wingspar. The many small windows in the rear part of the fuselage were made out of Perspex and hung in a Dural framework. The belly of the fuselage had two large doors with perspex windows, helpful for observation. There was also a bomb bay that could hold a 400 kg bombload. The rear part of the fuselage ended in a beautiful conical turret that could turn completely around its axis, giving the rear gunner a full 360 degree aim. The machine gun could be aimed by opening perspex panels running the full length of the turret. The wingspars went through the cockpit, right behind the pilot, and before the rear gunners compartment. 550 Liter fuel tanks with a reserve tank of of 150 liters were located in the wing, between the fuselage and the engine nacelles.

The wing edges, on both sides of the engine, contained the oil tanks. The outer parts of the wings were also made out of wood covered with triplex, glued together the same way Fokker used with their successful range of passenger planes and with plywood arches. All control flaps were made out of a Chromemolybdenum steel frame covered with linen. From the firewall on, the engine covers and struts were made out of aluminum. Directly behind the landing gear compartments the twin booms were again made of aluminum. The horizontal stabilizer, between the tail booms was also made out of aluminum and had the tail wheel in the middle, while the rudders were covered in canvas. The main landing gear was retractable into the engine nacelles.

Fokker decided to send the G1 to the Paris Air Show (which in those days did not have a flying display but only a static exhibition in the Grand Palais) even before its first flight, anticipating a lot of interest. His expectation was correct, with the G1 becoming the sensation of the show. The prototype was hung from the roof with steel cables between aircraft of the Polish and Russian manufacturers. The concept of a twin-boom twin-engined fighter, later adopted for the Lockheed P-38 Lightning, was quite revolutionary at the time, and the new aircraft was the centre of much critical appraisal. Interest was also generated as a result of the heavy armament of 8 machine guns in the nose. The G1 was given the nickname Le Faucheur (Mower) by the French and “Reaper” by the English, nicknames that pointed to the heavy armament in the nose. There is some doubt that the French came up with that name themselves; a lot of people think that Fokker made that name up himself. While the G1’s twin-engine, twin-boom design was also used for the Lockheed P-38 Lightning, conceived and designed around the same time, it is unlikely that the P-38 Lightning designed was derived from the slightly earlier Fokker G1 design.

After the Paris Air Show, the G1 was taken to Eindhoven/Welschap airfield, from where its first flight was made on 16 March 1937. A Czech pilot, Maresc, main test pilot for the Czechoslovakian government and senior pilot of the manufacturer Avia, made the maiden flight with the prototype (registration code X-2, and painted in green with medium blue belly). The flight went without flaws and after 20 minutes the pilot landed again. For the audience the G1 was a spectacularly promising plane that had minor problems. After 4 test flights this proved to be not quite so true. On the fifth test flight, problems occurred with one of the Hispano Suiza engines - due to overheating the engine broke down and threw several parts out through the exhaust pipes. Before this incident it was already well known that the Hispano engines were badly designed. One of the tail booms was also damaged.

The G1 was initially powered by two 559kW Hispano-Suiza 80-82 counter-rotating radial engines, but problems with these prototype units (they used too much oil) resulted in a change to similarly rated Pratt & Whitney SB4-G Twin Wasp Juniors during rebuilding (after the G1 suffered brake failure and rammed a hangar at Schiphol on 4 July 1937). A quick and dirty solution was to add extra oil coolers, placed underneath the engines. This solution was not very elegant and finally Fokker did choose another engine, the Pratt & Wittney Jr. SB4-G This engine produced less power but was much more reliable. For the Dutch Air Force, other engines were mounted; the more powerful Bristol Mercury VIII engines that where also used for the Fokker DXXI (this engine was specified as standard by the Dutch Air Force for all its aircraft). The aircraft design consequently had to be adjusted as the engines had a larger diameter and a different shape and the propellers were larger, meaning the engines had to be moved further away from the fuselage. The wider central wing meant that the fuel tank capacity could be increased.

The tail design was also slightly changed. The redesign incorprated higher landing gear to keep the propeller of the ground. These changes were incorporated in the X2 prototype which satisfied the LVA. Actually, the designers wished to replace the engines with Rolls-Royce Merlin engines (which would have made the G1 the fastest fighter in the air at the time), but those were not available for export from the UK. The design of the nose section of the G1 also caused problems. The armament chosen by the Dutch Air Force, 8 machine guns in the nose, caused the aircraft to become nose-heavy and made the plane difficult to manage during take-off and landing. Several G-1’s ground looped during landing and a good solution for this problem was not found although in 1939 there was a plan to give the G.1 a different setup. In this design modification, 4 of the machineguns were relocated to the bomb bay firing from underneath the pilot. In use with the Dutch, the machineguns also proved to be very unreliable, partly due to the low temperatures at high altitude. This sensitivity to subzero temperatures was partially resolved by using a different lubricant. Despite that the armament kept on causing problems; firing them on the ground was no problem, but in the air usually 2 or 3 of them jammed. This problem was not solved by the Dutch.

| Type |

2 - 3 seat heavy fighter |

| Engine |

2 Bristol Mercury VIII |

| Dimensions |

Length 11,50 m, height 3,40 m, span 17,15 m, wing area 38,30 m2 |

| Weights |

Empty 3360 kg, take-off weight 4800 kg |

| Performance |

Max. speed 475 km/h, cruising speed 355 km/h, service ceiling 9300 m, range 1400 km |

| Armament |

9 7,9 mm MG, bombs 400 kg |