The Benz Bz.IV was a German six-cylinder, water-cooled, inline engine developed for aircraft use. Deliveries began in 1916 and some 6,400 were produced.

The Bz.IV was a dual-camshaft design, with two intake and two exhaust valves per cylinder. The cylinders were cast iron surrounded by a sheet metal cooling jacket. The crankcase was aluminium and pistons were initially steel but later versions had aluminium pistons. A high compression version of the engine (Bz IVü) was produced from 1917 onwards and can be recognised by the red bands painted on each cylinder.

Components

Valvetrain: Twin inlet and exhaust valves operated by pushrod actuated double rockers

Fuel system: Two Benz 2-jet carburettors feeding three cylinders each

Fuel type: Gasoline specific gravity 0.72

Oil system: Pressure feed at 0.2 MPa (28 psi): 50% Vacuum Heavy, 50% Sternol

REPORT ON ALUMINIUM PISTONS FROM 230 H.P. BENZ ENGINES.

Flight JULY 4, 1918.

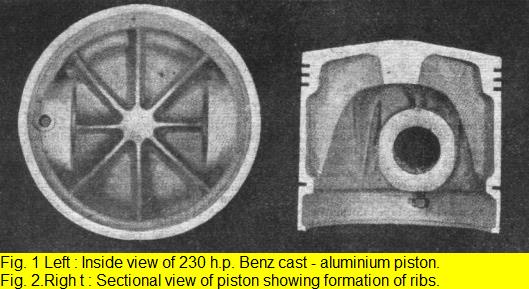

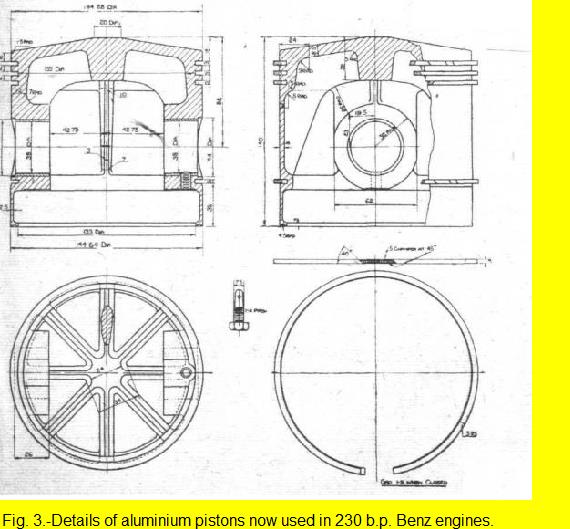

A 230 h.p. Benz engine, No. 31,560, taken from the Aviatik biplane, G. 130, captured on February 12th, 1918, was found to be fitted with aluminium pistorrs. As these are the first aluminium pistons to be found in a captured enemy aero engine in service, a detailed report of their design, together with a chemical analysis of the alloy, should be of interest. The pistons weigh 4 lbs. 8 1/2 ozs, each, without rings, which weigh 1.5 ozs. each. The total weight of the complete piston, with rings and gudgeon pin set screw, is 4 lbs. 14 1/2 ozs., as compared with the standard cast-iron piston, which weighs 6 lbs. 111/2 ozs. The gudgeon pins and connecting-rods are of standard Benz design, as also is the rest of the engine to which these pistons were fitted. The design of the standard cast-iron Benz piston, which is fitted with a conical steel support, riveted to the inside of the piston crown, and which bears upon the centre portion of the gudgeon pin through a slot cut in the connecting-rod small end, is well known. Unlike the standard cast-iron piston, the domed head of the sand-cast aluminium piston is supported and stengthened by eight webs radiating from a central boss in the piston crown. The formation and shape of the webs is clearly shown in the photographs and sectional drawings of the piston.

Three cast-iron rings are fitted above the gudgeon pin, and one scraper ring is provided below the gudgeon pin. All rings are concentric and are machine hammered on the inside. It will be noticed that the rings are all exceptionally deep in section, being 5.25 mm. deep and only 3 mm. wide vertically. The piston ring gap measured in position in a standard 230 h.p. cylinder was found to be exceptionally wide, i.e., 1.9 mm. As may be seen in Fig. 2, the gudgeon pin biases are fitted with steel bushes 2 mm. thick. These are cast into the bosses in the usual way. The gudgeon pins are 38 mm. diameter, and the gudgeon pin bosses are 65 mm. diameter. The method of fixing the gudgeon pin by a hexagon-headed set screw and split pin is standard Benz practice.

An annular semi-circular groove 4.5 radius is machined on the bottom lip of the piston, as shown in the section drawing, Fig. 3 ; and the inside of the skirt is machined inside up as fax as the reinforcing rib of the scraper ring directly below toe gudgeon pin.

Further details of the design of these aluminium pistons are shown in the illustrations, and the chemical composition of the alloy from a metallurgical analysis carried out at R.A.E. is as follows : Copper per cent., 6.02 ; zinc per cent., 11.13.; iron per cent., 1.42; silicon, 0.31; tin per cent.,nil; nickel per cent., nil ; manganese per cent., trace ; magnesium per cent., trace.

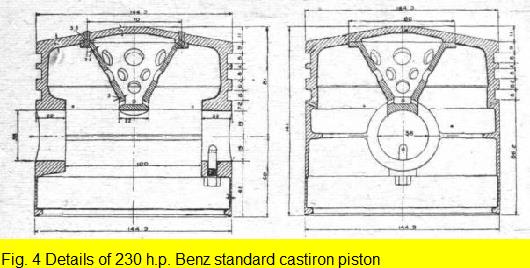

As the engine from which these pistons were taken was found to be too badly damaged to carry out a test, it has been impossible to ascertain the increased relative efficiency between this engine and the standard 230 h.p. Benz. The compression ratio, however, is apparently slightly higher in the engines fitted with the aluminium pistons, and, as will be seen in the detailed drawing ol the cast-iron Benz piston, which is given in Fig. 4 for reference, the distance between the top of the piston and the central axis of the gudgeon pin is increased from 70 mm. to 71 mm., which gives approximately 16.51 cubic cm. less in the clearance volume of each cylinder in engines fitted. with these aluminium pistons, which gives a compression ratio of 5 to 1 instead of 4,94 t o 1. . .

Aircraft using Benz IV

LFG V 13

LVG C VI

Friedrichshafen FF 49c

LFG FF 71a

| Type |

6 cylinder In line

|

Compressor |

|

Reduction Gear |

|

Length |

1990 mm |

| Operation |

4 stroke |

Bore |

145 mm |

Compression ratio |

4,8 |

Height |

1150 mm |

| Mixture |

Carburettor |

Stroke |

190 mm |

Fuel consumption |

228 g/hph |

Width |

530 mm |

| Cooling |

Water |

Displacement |

18800 cm3 |

Oil consumption |

10 g/hph |

Weight |

370 kg |

| Power output |

Start 275 hp, climb 230 hp, cont. 200 hp |

|

|

|

|

|

|