Leipzig, Flugplatz Mockau

The DFW or Deutschen Flugzeug Werke was establishcd in 1911 at Leipzig-Lindenthal to build

French-designed Farman types. At this time the firm had only 60 workers, but this number had

increased to 2,825 by 1918. In 1914 DFW had already built 107 aircraft and in 1917 no fewer than

820 of its own design CV-type reconnaissance aircraft. Two thousand of this very successful

aircraft were built in the first World War at DFlW as well as several thousand others at various other

licensed firms.

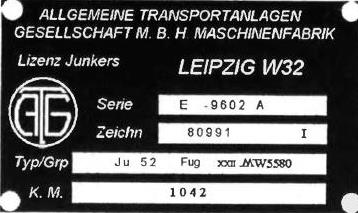

In 1919, the firm became ATG, or Allgemeine Transportanlagen GmbH, for building transport equip-

ment. Early in 1933 Koppenberg had purchased ATG for Flicks Mitteldeutsche Stahlwerke. On 24

March of the same year Milch had entered into talks with the ATG wagon factory with regard to the

production of Junkers aircraft. The agreement was facilitated by the fact that soon Koppenbcrg was

to become Junkers general manager.

Under the ABC Programme of 13 December 1933 a total of 179 Junkers 52 aircraft were ordered

from four factories: ATG, Hamburger Flugzeugbau, Dessauer Waggon and Junkers. The main aim of

the programme was to train personnel for metal aircraft construction. ATG as the other plants, made

only parts for the main Junkers plant at Dessau.

Under the following Rhineland programme of 1934 a further 450 Ju 52s were ordered from the same

four firms: most of these were delivered in 1935. In this year ATG had already assembled 32 aircraft

for the following programme, although the first metal aircraft built by ATG were 32 Junkers W.33 in

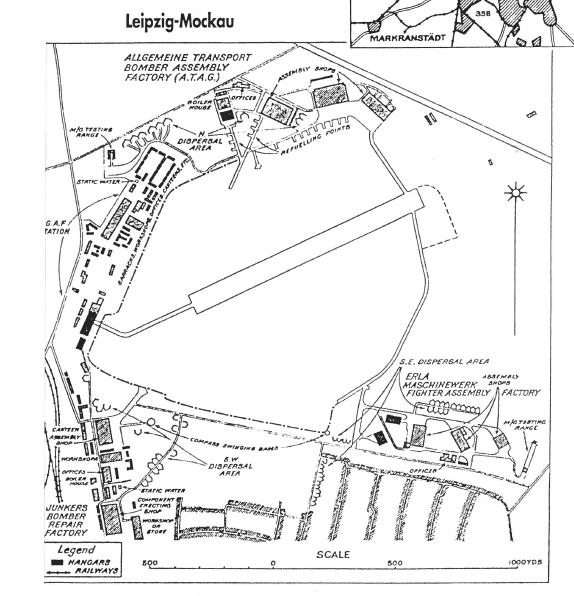

1934-35. In 1935 a new plant was established by ATG at Leipzig-Mockau mainly for final assembly

and test of ATG-built aircraft. The old Lindenthal plant was used as before, for part production. In July

1935 the workforce of ATG had reached 3,902 men. The company became more and more important.

In 1936 a workforce of 4,500 including 2,400 production workers with 5.8 million working hours

realised 121 aircraft, including 72 Ju 52s and 49 Junkers W.34s. In 1937 the manpower had increa-

sed to 5.100; 2,750 production workers built 296 aircraft, 154 W.34s, 50 Ju 52s, and 92 Ju 86D

bombers, working 6.6 million hours.

By January 1938 the personnel reached 6,000, with 3,250 production workers and by 1 October 1938,

6,356, with 3,432 production workers. The floorspace was now 62,500 m2. In spite of the fact that the

total working hours were 7.8 million, production dropped to 112 aircraft. The reason was the decrease

of the relatively small and simple W.34 to only 45, and the start of the production of the more compli-

cated He 111 bombers, of which 40 were produced in this year. The number of new Ju 86s was also

decreased to 27, but in the same time the firm started to rebuild many Ju 86s with new engines.

In 1939 the number of new aircraft produced jumped to 234, in spite of the halt of the W.34 construc.

tion. In this year ATG built 160 He 111s, and 74 Ju 86s. Of the latter type delivery was divided between

the new Ju 86G sub-types and many export aircraft. ATG for example built 16 aircraft in parts for the Swedish SAAB firm. The rebuilding of the old Ju 86A/D continued. In December 1939 the workforce of ATG reached 9,131.

1940 signified many new facets in the production programmes. The final 126 He 111 were assembled in addition to 40 E, 20 H-1,140 H-2 and 126 H-3 and H-4 sub-types. These 326 bombers were new aircraft, but some He 111 rebuilds were also completed. In 1940 the building of Ju 52 transport Aircraft was restarted: already 120 in 1940, 201 in 1941, 204 in 1942, 258 in 1943 and 101 in the first half of 1944. 662 of the Ju 52s built by ATG received the W.Nr between 2801 and 3462: the rest in the W.Nr #500,000 and 501,000 bracket. But from 1940 the most important type on the ATG production line was the Ju 88 bomber: firstly the A-1 then the A-5 and after the A-4 and other sub-types. ATG built the fuselage and tails, but not the wings. Final assembly and test flying was carried out at Leipzig Mockau. 190 were built in 1940, 240 in 1941, 300 in 1942, 360 in 1943 and a final 40 up until June 1944. According

to other sources a total of 1,286 Ju 88s were built at ATG. It is difficult to obtain an exact figure as ATG also rebuilt many badly damaged aircraft of their own manufacture.

The following programme at Leipzig-Mockau was the building of the Ju 188 bomber and reconnaissance plane. The first was assembled in January 1944. Several sub-types were constructed, including the A-2 and from the summer also the S-1 The production was disrupted by several bombing raids by the USAAF, such as on 29 May 1944 and 20 July 1944.

Nevertheless ATG continued the building of the aircraft until January 1945; a total of 244 Ju 188A-2, D, S,Ts were assembled.

The firm built also parts for its aircraft, the fuselage and tail assemblies but not the wings. In parallel with the Ju 188 production ATG also entered into the very important Ju 388 programme in 1944. In August 1944 the first Ju 388 fast bomber was produced at Merseburg, followed by the Ju 388L-1 in October of that year. ATG was to build 100 aircraft a month; as usual the firm assembled fuselage and tail sections but not wings. Parts for the assembly of many aircraft were produced, but ATG only managed assembly of about 40 aircraft when in February 1945 the production programme was halted due to the worsening strategic situation. At this time the firm was instructed to tool up for the production of the very modern and fast Ta 152C fighter. Due to the relatively abrupt end to the war, ATG could only produce a number of component parts, but no aircraft. All the Components were captured by the Soviet troops, who completely dismantled the plant and in 1946 along with all the production machinery sent everything to the Soviet Union.

In 1952 ATG reappeared in West Germany, the same year merging with the Siebel firm to form SIAT, who resumed aircraft production in 1956.

Stammwerk Schönauer Straße 101

Werk II Zschortauer Straße 22 (from November 1934)

Werk III Seehausener Straße (Flughafen Leipzig-Mockau, from Mai 1935)

Werk IV Ludwig-Hupfeld-Straße 12/14

Werk V Anton-Zickmantel-Straße 50

Werk VI Messegelände, Messehalle 15 (from 1939)

Werk VII Nonnenstraße 17-21 (Elektrik und Funktechnik, from 1939)